- Shipping

- What are your shipping policies?

Designs for mantels and other products may need to be modified to accommodate safe shipping and handling. All design modifications must be approved prior to production. Stone Mountain Castings & Design’s shipping includes the following:

- Shipping with curbside delivery to destinations in the lower 48 U.S. states on every item we sell. All other locations will be quoted.

- Curbside delivery to a freight-accessible address.

- Residential delivery with a lift-gate.

- As defined by the trucking industry, “residential delivery” means “curbside delivery” in a residential area.

- Moving your shipment from the curb to your home at the time of delivery is not included.

- Residential delivery services DO NOT include inside delivery, installation, or un-crating.

- Residential delivery with a lift-gate requires an appointment for the curbside delivery.

- The carrier will contact you to set a delivery appointment.

Shipments are fully insured against damage. Shipping lead time is three to five business days after pickup from our facilities.

Delivery

Delivery appointments are generally within a two-hour window. We always ask that the trucking company use a lift-gate truck for delivery, but this is not always possible, so please have two or three able-bodied individuals ready to unload the crate(s) from the delivery truck. In rare cases where the location is remote or in residential areas that do not allow large trucks, the customer may have to arrange a second delivery.

Lift-gate sizes vary based on the carrier and terminal and cannot be guaranteed to accommodate all orders. Customers ordering oversized crates will need to arrange for end-of-delivery services including the possibility of forklift service, terminal pickup, or hand-off loading.

92 3/8” x 38 3/8” x 30” is the maximum oversized shipping crate size. The customer is responsible for providing correct shipping information related to the delivery site and accessibility. Orders will not be reconsigned without customer approval and payment of all applicable fees. Due to liability, freight trucks will not drive on private property. Non-paved roads, tight turns, steep embankments, high-rise buildings, or otherwise “difficult” delivery locations or situations may mean that you have to pay for additional delivery services.

Un-Crating and Accepting Delivery

You will need the following on hand to help open the carton: knife, hammer, and pry bar. We are committed to making sure you are satisfied with our products. Your order is inspected prior to shipment to ensure all items are in excellent condition before they leave our facilities. Although our products are packaged securely to prevent any damage, it’s possible that in rare cases, damages may occur during shipment.

The customer is responsible for inspecting all merchandise prior to accepting the delivery. Before signing for receipt of the product, all product pieces must be uncrated and the contents inspected for damage. During the un-crating process, care must be taken to protect the integrity of the contents.

Never stack stone materials upon one another without carefully placing foam packing material between them. If there is damage to the carton or the product, please write “CONTENTS DAMAGED” clearly on the delivery receipt that the driver is asking you to sign. Then sign. This insures that your damage issue will be easily resolved.

At any point, should any damage be identified, Stone Mountain Castings & Design MUST be notified via telephone at (801) 495-9797 and/or email at [email protected] within a 24-hour period. Such email notification MUST include photographic evidence of the damage(s) along with photographs of the crating and packing components and a delivery receipt with “CONTENTS DAMAGED” clearly visible.

We cannot be held responsible for the cost of repairs or replacement of damaged items if there is no notation on the Freight Delivery Receipt or pictures of the damage. Contact us within 24 hours to initiate a damage claim. Failure to inspect and document merchandise voids the insurance warranty and replacement coverage.

Other Shipping Considerations

Customers are able to ship at their own risk or make their own shipping arrangements if desired. Customers may give us a commercial ship-to-delivery address at the time of order, preferably with a loading dock, pallet jack, and/or forklift. Customers may ask us to ship to our carrier’s closest local terminal where they can pick up the shipment.

- Custom Projects

- How do I order a custom or natural stone mantel?

The process for ordering custom mantels is almost the same as ordering one of our standard mantels. To be able to give you a price, we would need some images of the mantel design. We would also need the overall finished mantel dimensions.

- Do you offer custom mantel designs and natural stone mantels for out-of-state customers?

Yes, we do! If you can find one of our standard mantels to use, the price will be almost half of a custom mantel. The cost for a custom mantel is generally an extra $1,500 for the one-time use of mold and labor. Natural stone mantels generally start at $5,000.

- Do you offer range hoods for out-of-state customers?

Unfortunately, we do not ship range hoods due to their complexity and many other variables. They are only available for local projects located in Utah. For more information about range hoods or custom mantels, call us today.

- Fireplace Mantels

- Do you offer trade discounts?

We work almost exclusively with members of the trade. Our pricing already reflects the discounts available, with the exception of accounts where there is a showroom for our product or bulk orders. For further information about the pricing of our mantels, give us a call today.

- Is there a way to get your Essex, Wasatch, or Diez mantels without the horizontal seams?

Unfortunately, our shipping brokers will not insure the mantel if it’s shipped in one piece without the horizontal seams. As a result, we have had customers pick up their mantels directly at our facility.

Previous customers have also arranged for physical pickup from our facility with a dedicated box truck or trailer. This option ensures that the crate will not be moved from truck to truck at each terminal so there is no risk of damage. We have heard of prices ranging from $5,500 and up for this service. It really depends on where you’re located. If you want to check around, our manufacturing location is in Draper Utah.

Once the mantel is installed, some customers have used sheetrock mudding compound or 10-minute mud to fill in the seams. They then sand the dry compound, prime, and paint the mantel until the seams are gone.

- How do I install a mantel?

Mantels don’t have to be confusing to install! You can watch our installation video on YouTube and follow the provided instructions to make the process simpler. Click here to view it!

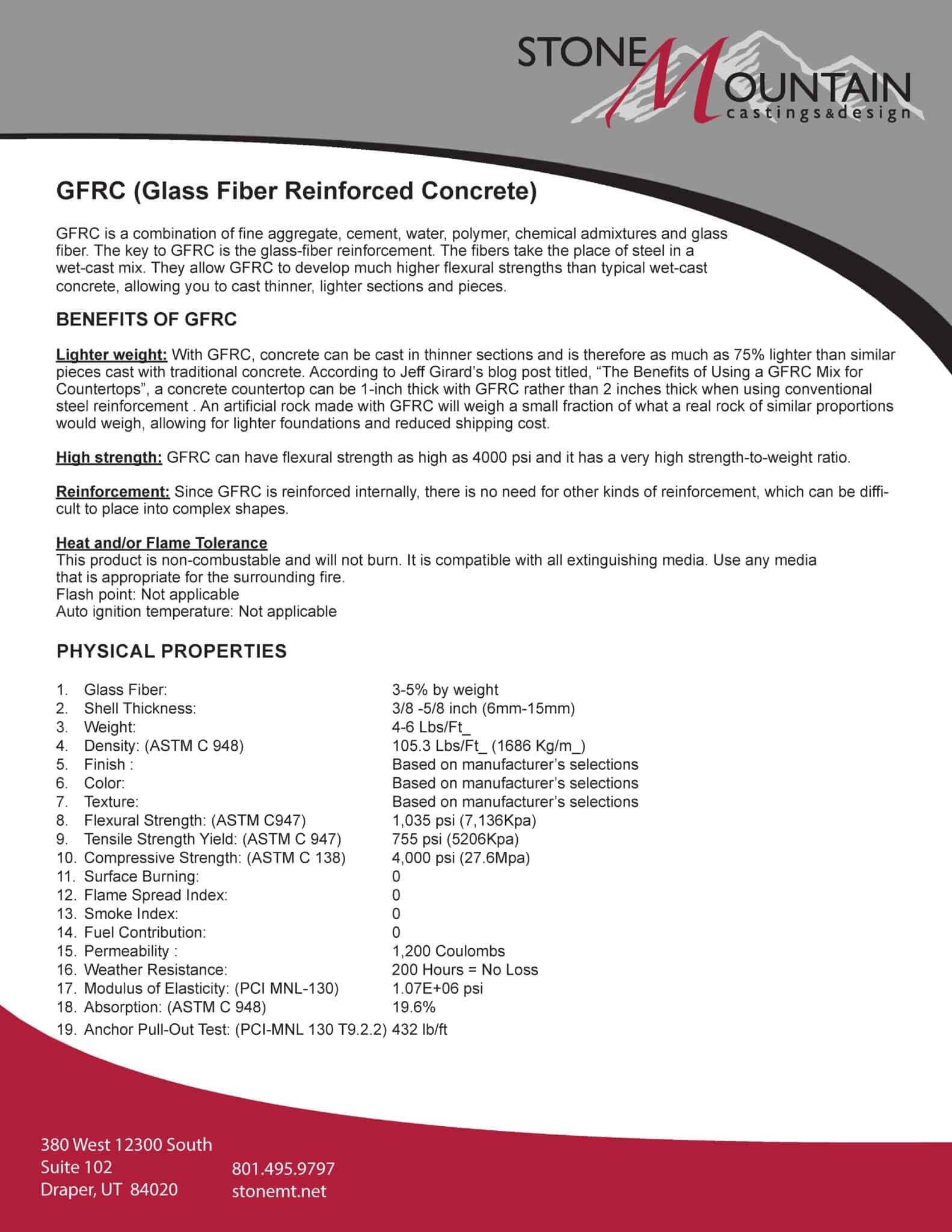

- What are your products made with?

Our Products are made of GFRC (Glass Fiber Reinforced Concrete)

GFRC is a combination of fine aggregate, cement, water, polymer, chemical admixtures and glass fiber. The key to GFRC is the glass-fiber reinforcement. The fibers take the place of steel in a wet-cast mix. They allow GFRC to develop much higher flexural strengths than typical wet-cast concrete, allowing you to cast thinner, lighter sections and pieces.

BENEFITS OF GFRC

With GFRC, concrete can be cast in thinner sections and is therefore as much as 75% lighter than similar pieces cast with traditional concrete. According to Jeff Girard’s blog post titled, “The Benefits of Using a GFRC Mix for Countertops”, a concrete countertop can be 1-inch thick with GFRC rather than 2 inches thick when using conventional steel reinforcement . An artificial rock made with GFRC will weigh a small fraction of what a real rock of similar proportions would weigh, allowing for lighter foundations and reduced shipping cost.

High strength: GFRC can have flexural strength as high as 4000 psi and it has a very high strength-to-weight ratio.

Reinforcement: Since GFRC is reinforced internally, there is no need for other kinds of reinforcement, which can be difficult to place into complex shapes.

Heat and/or Flame Tolerance

This product is non-combustable and will not burn. It is compatible with all extinguishing media. Use any media that is appropriate for the surrounding fire.

Flash point: Not applicable

Auto ignition temperature: Not applicable

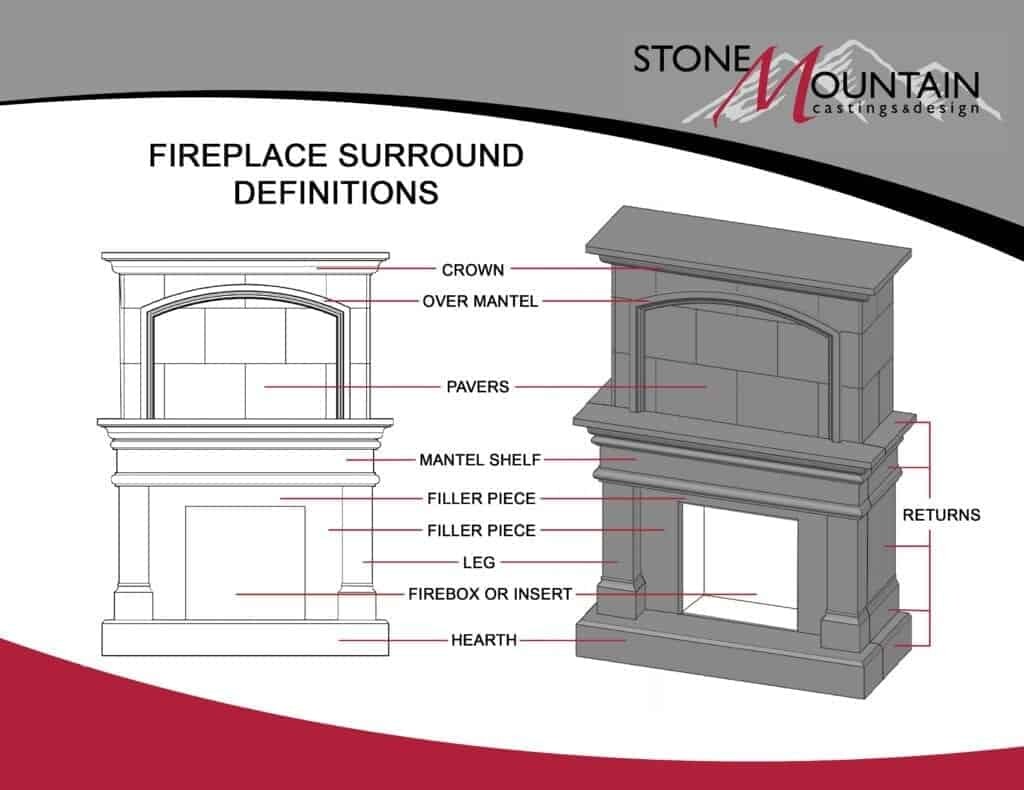

- What are the different pieces of a fireplace mantel called?

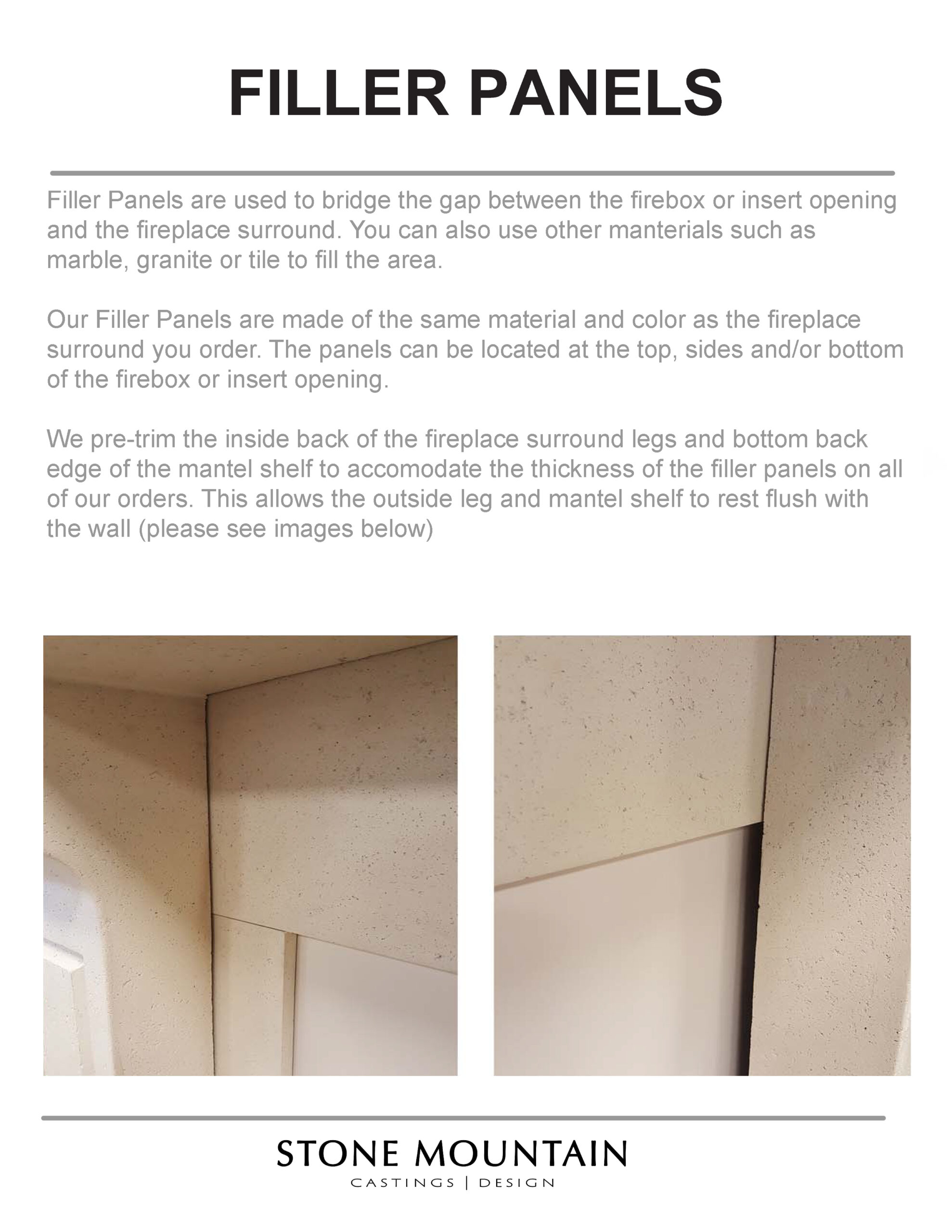

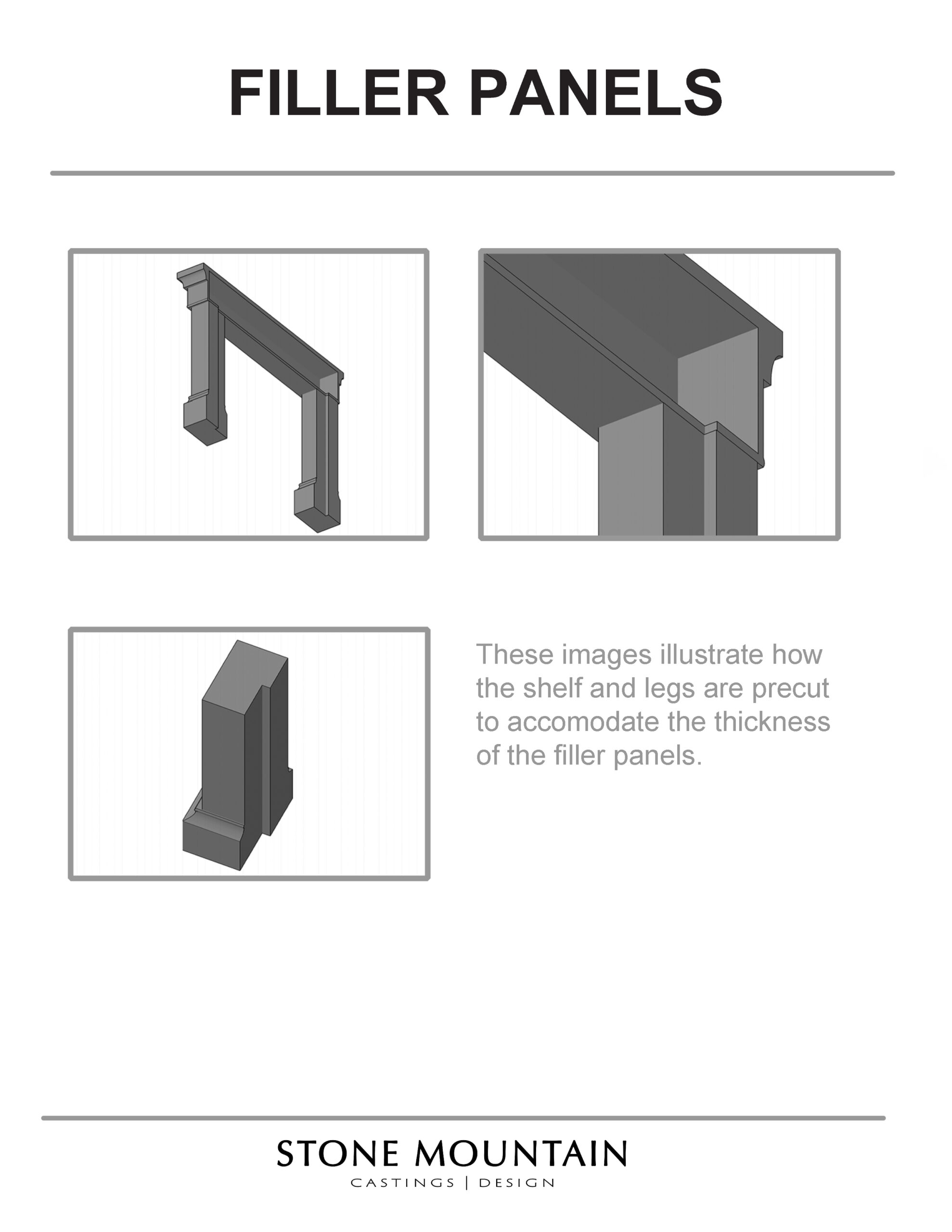

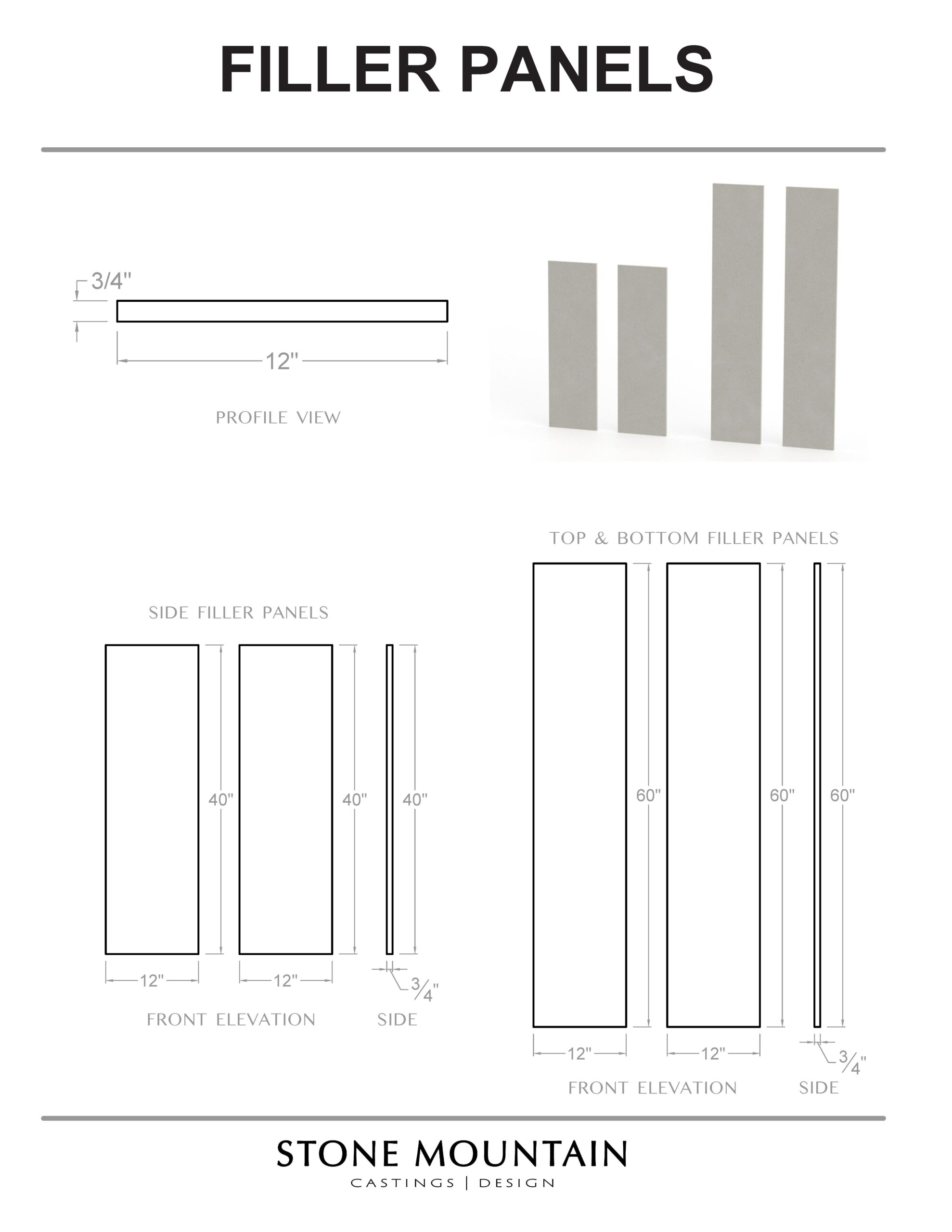

- What are filler panels?

If there is any type of gap or space between the insert and the mantel shelf and legs, we provide filler panels to fill the space. Filler panels are included with the mantel price. For more information on panels for mantels, get ahold of our professionals today.

- Care and Maintenance

DO NOT SAND OR USE ABRASIVE MATERIALS ON PRODUCTS

Precast products are sealed with a high quality concrete sealer prior to shipment or installation. The product can still be stained as it is a natural porous product. Please review the following guidelines to keeping your mantel in pristine condition.

Consistently and regularly vacuum for dust. Immediately wipe up any spills. For a deeper clean, use a diluted floor cleaning solution, making sure to always use a white cloth. We have been told Magic Eraser works well, as do Scotch Brite pads for tougher areas. A last resort option is using clear acetone. Make sure to ONLY use a damp white cloth without any dye or pigment, as this can bleed into the precast material and permanently alter the color as well as strip finish. Make sure the rag is damp and use long strokes so that the finish stays as consistent as possible.

If in a high traffic area or is an exterior application, we recommend resealing the product once a year with a high quality concrete sealer. Prior to application, make sure all surfaces have been thoroughly cleaned and prepared.

- Can I use an electric fireplace with a mantel?

The electric insert will need to be recessed into the wall instead of mounted. Our mantels need a flat surface to attach to and are not made to accommodate the thickness of a wall-mounted fireplace. To learn more about custom mantels, reach out to us today!

- Do you offer a warranty?

Stone Mountain Castings & Design’s products are warranted to be free of any major design flaws and material defects for a period of one year from the date of delivery. Please note that material defects exclude natural color and texture variation, typically inherent in the production of cast stone. For more information on the warranties of our custom mantels, don’t hesitate to call us today!

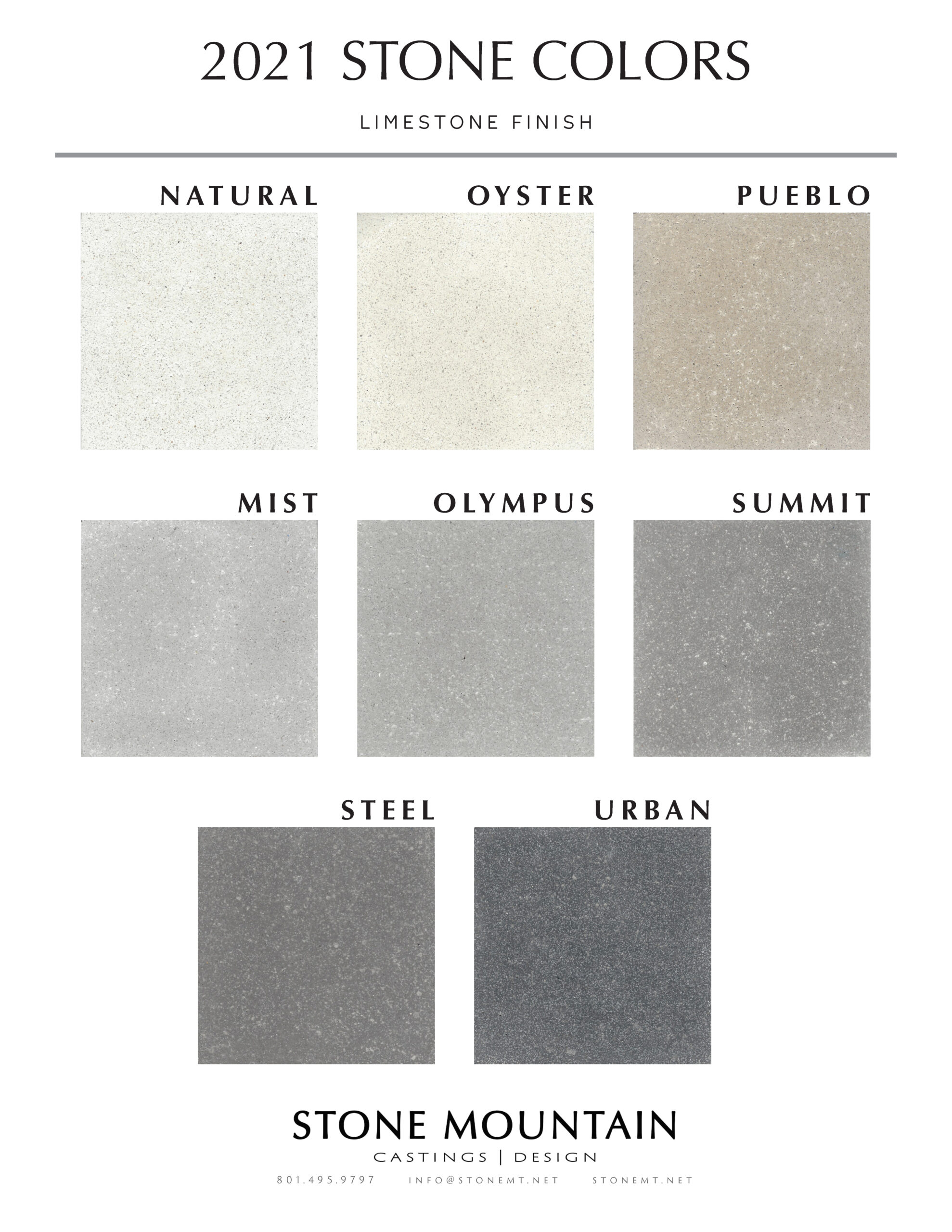

- Color Samples

- How Do I Order Color Samples?

We offer color samples through our online store. Click here to order samples.